Nylon staining inhibitor for dyeing of nylon/cellulose blends

Since there is diversity in the consumer's preference for color quality, dyeing fastness in nylon/cotton or rayon blends varies accordingly.

It is necessary, therefore, to manage various dyeing techniques in accordance with the price of clothing of the consumer's preference, as well as the use of dyestuffs of various grades, from high, mid to low, depending on the desired quality and prices.

It is often believed that the use of high grade dyestuff causes less trouble and is safe, and no question is raised for the selection of anti-nylon-staining agent as long as it is compatible with these particular kinds of dye.

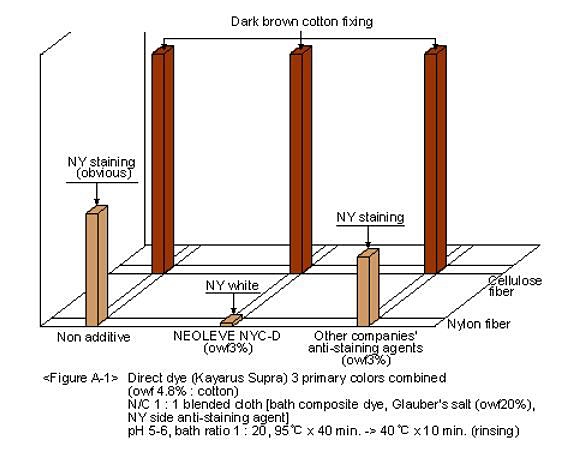

However, because of the circumstances mentioned earlier, certain devices are called for in the making of anti-staining agents for nylon. In dyeing nylon/cellulose blends, direct or reactive dyestuff, used on the cellulose side, causes considerable staining on nylon.

The more staining produced, the poorer colorfastness to washing/light and fixation to cellulose will result. Problems such as poor reproducibility will easily occur with color tones of direct/reactive dyes that have caused staining to nylon often differing from the original tones fixed to the cellulose.

As there is more variation in the consumer's preference (quality and price), dyeing problems such as the above occur more frequently.

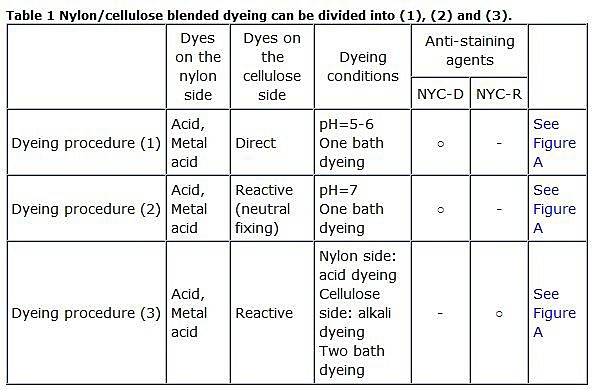

Neoleve (anti-staining agent) series according to 3 different dyeing methods

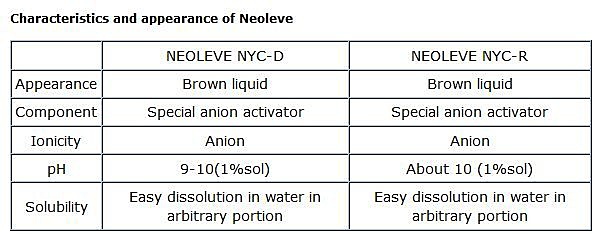

Neoleve NYC-D has been developed for the prevention of nylon staining in neutral to acid dyeing of nylon/cellulose materials.

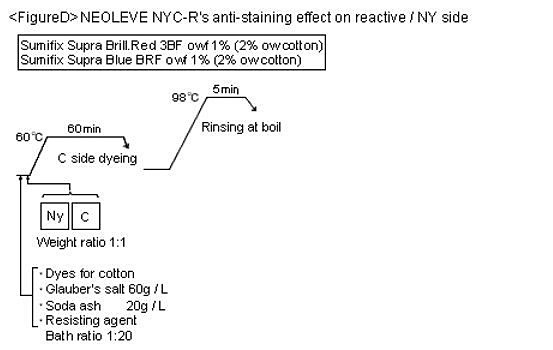

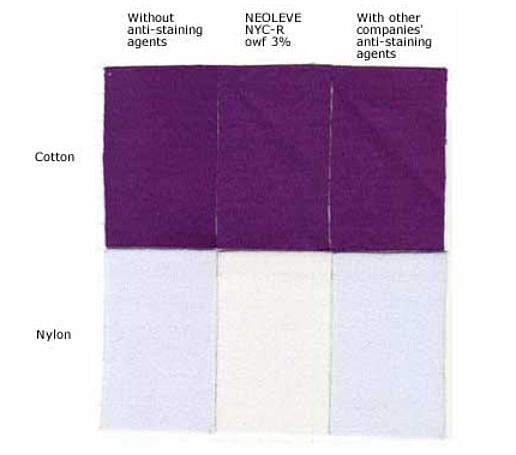

Equally, as shown in Table 1 (3), Neoleve NYC-R is suitable for alkaline deep-dyeing, in which improved prevention of staining on the nylon side can be expected.

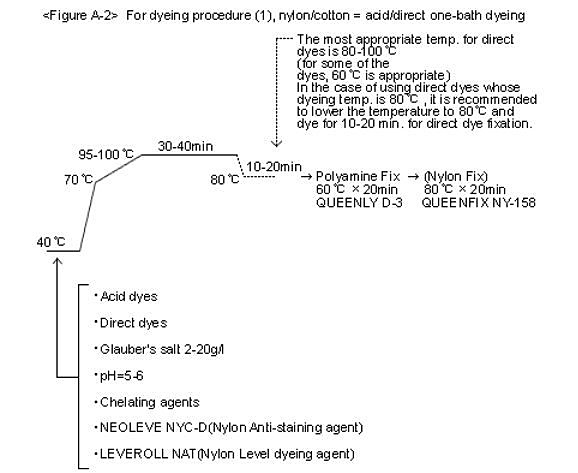

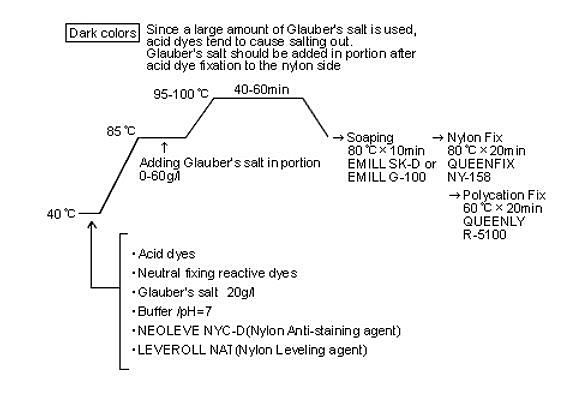

For dyeing method (1), adding Glauber's salt in portion is vital.

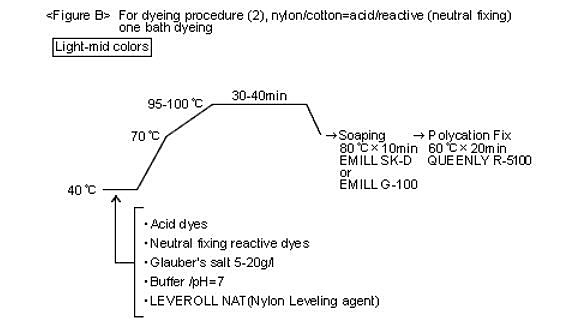

In dyeing method (2), the hand of nylon is superior

In dyeing method (3), Neoleve NYC-R can facilitate superior deep dyeing

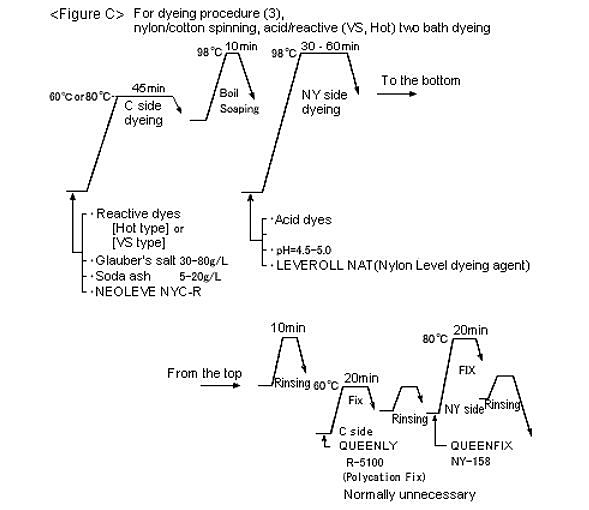

This is two-bath dyeing of nylon/cotton blend with acid/reactive dyestuff. Neoleve NYC-R is an anti-nylon-staining agent most suitable for this procedure.

In order to attain high colorfastness in this dyeing method, reactive dyestuff is used for the cellulose side, and acid dyestuff with high fastness for the nylon side.

As reactive dyes are for the alkali side and acid dyes for the acid side, normally, one-bath dyeing is not possible.

Dyeing of cellulose is carried out first, then follows soaping in a boiling bath before dyeing the nylon side.

If the cellulose side is dyed after the nylon side, acid dye fixed to nylon can easily be washed off during soaping in a boiling bath after cellulose dyeing.

In cases of using vinylsulfone-based reactive dyestuff, careful selection is required since the degree of staining varies depending on the type of dye.

Examples of Neoleve use according to dyeing method used

Ways of using the two types of Neoleve vary depending on the mix ratio of nylon, the kind of substrate and dye concentration, however, the use of 1-3% o.w.f. is generally a standard.

Preliminary testing is necessary as Neoleve's anti-staining effect may deteriorate due to the simultaneous use of some leveling agents during dyeing of nylon.